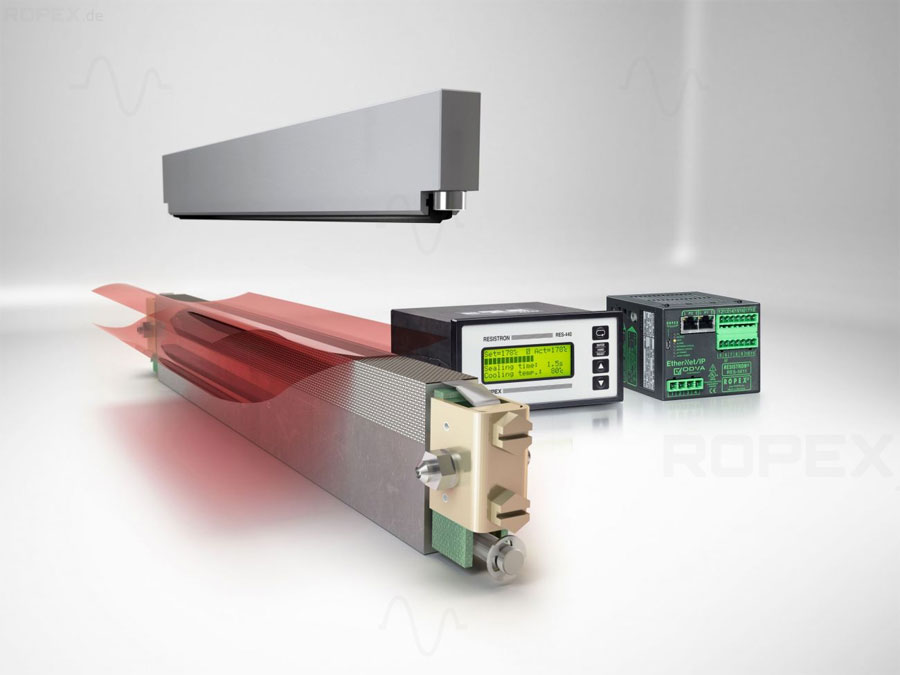

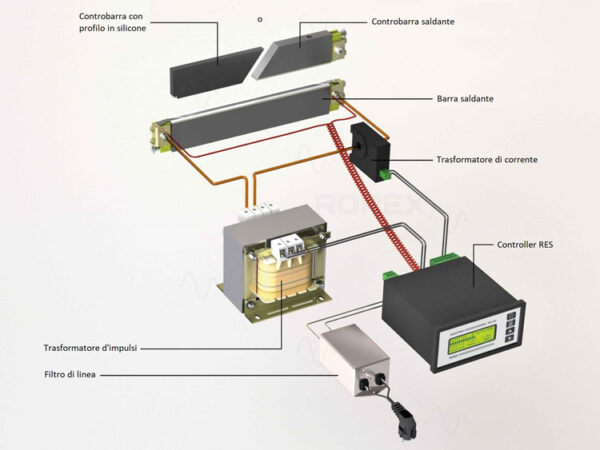

The RESISTRON system includes line filter, controller, impulse transformer, current transformer and heat-sealing bar(s). Depending by the needs it can be foreseen 2D and 2D sealing tools, different types of counterbars, air or liquid cooling systems and other optional components.

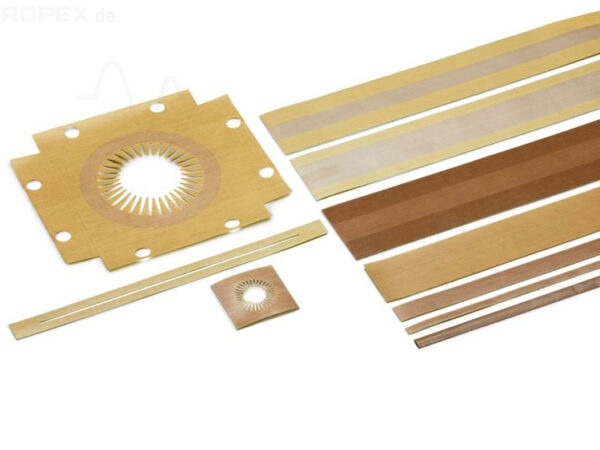

This technology makes possible to carry out the only sealing, the only “thermomechanical” cutting or the combination named cut& seal that does the two actions in the same time. It can be used the standard straight bars or 2D/3D shapes tools and with heated and inactive parts of the sealing path.

Once the information has been collected through the on-line questionnaire, ROPEX issue the “application report” which contains all the information related to the specific system (size of the cables, impulse transformer dimensioning, currents and voltages values, etc.) and the wiring diagram. ROPEX provides a sealing test laboratory service to verify in advance the feasibility and the results that can be obtained with the application of the impulse technology, also reducing the commissioning time of the machine/line. In case of need and for further information, you can contact us directly: