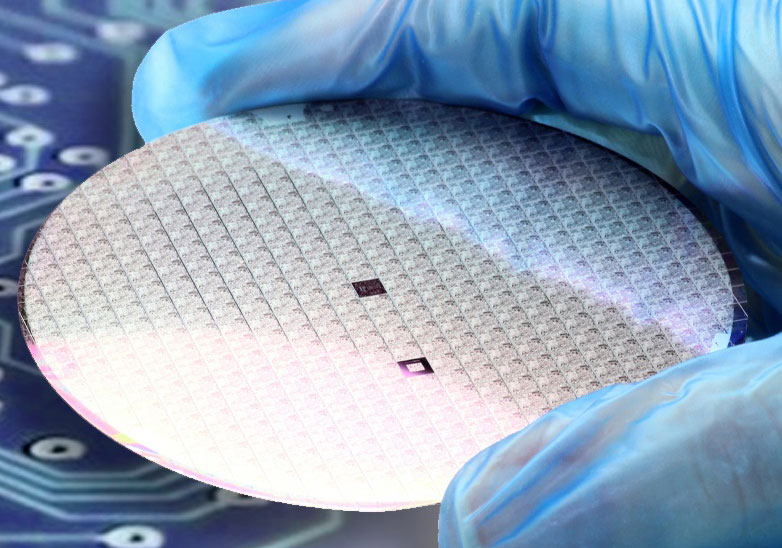

Silicon-on-sapphire (SOS) wafers are formed by depositing silicon on the sapphire substrate at very high temperatures.

Natural sapphire tends to contain impurities, so to obtain a pure crystal it has to grow in a controlled laboratory environment.

Sapphire ingots, once formed, are cut at a 60º angle, known as “Plan R”. This reveals the oxygen atoms present in the crystal and, since the spacing of these atoms is almost identical to that of a silicon crystal, the silicon itself can be deposited with extreme precision on the surface of the sapphire wafer.

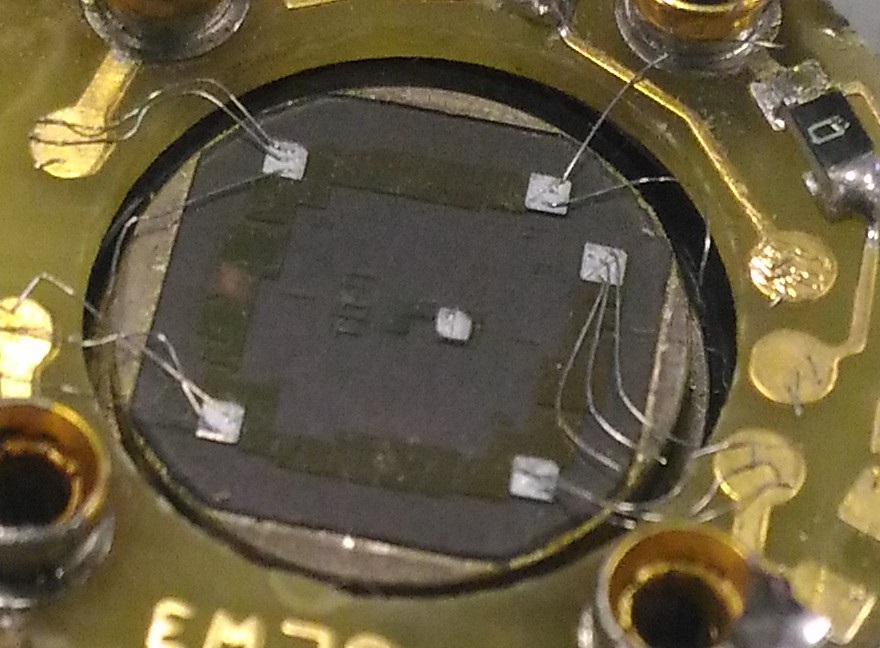

Doped silicon strain gauges are derived from the silicon layer, and the individual strain gauges are electrically isolated from each other thanks to the outstanding insulating characteristics of the sapphire substrate.